The final part of any printing process is choosing a finishing solution for your printed product. These can help to make your printed product even more striking, whether it’s by embellishing your logo, creating a tactile feel, adding dimension or even creating a sense of luxury.

Here are some of the most popular and visually-striking print and finishing solutions on the market today:

- Embossed or Debossed Finish

- Matte and Metallic Foil

- Matte Laminate

- Saddle-Stitch

- Anti-Scuff Laminate

- Soft-Touch Laminate

- Gloss Laminate

- Spot UV Varnish

- JET Varnish/ Scodix

- Binding Options

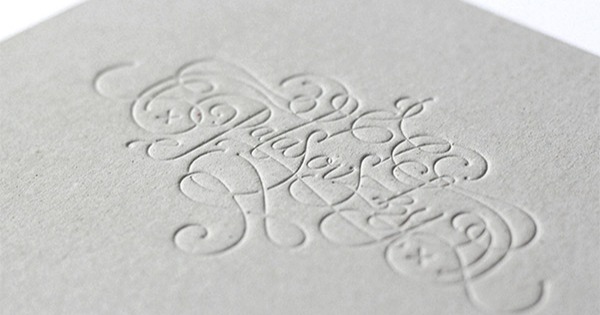

Embossed or Debossed Finish

Embossing and debossing are very simple but incredibly effective ways of finishing off your printed artworks. Embossing creates a raised relief whereas debossing creates a cavity.

By creating raised portions or lowered indentations in the print material, you can enhance the final product by adding dimension to the piece.

Image Credit: Pinterest

Image Credit: Pinterest

It can help to bring images to life and add a tactile feel to your work. It’s usually most effective when enhancing logos or creating textured backgrounds.

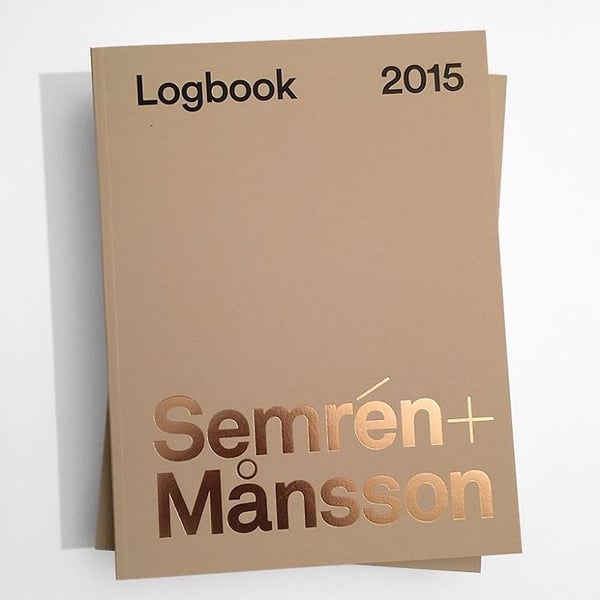

Matte and Metallic Foil

The addition of a foil finish to areas of your print creates a luxury aesthetic that’s irresistible to the eye of a consumer.

It’s a highly reflective finish and is versatile enough to work with most materials and substrates. In the process, foil is stamped to the print through heat and pressure which, in turn, irons out any unevenness in the material itself.

Using either matte or metallic foil means that these parts of any bespoke printed product will be consistent in brightness and opacity. They’re not subject to the variability that can affect metallic inks such as changes in ink distribution.

Image credit: Buromarks

Image credit: Buromarks

For a truly great visual impact, combine foiling with a deep debossed design to achieve a desirable finished product.

Matte Laminate

Sophisticated in visual appeal and durable in physical properties, matte laminate is a great choice.

Similar to creating an enhanced tactile feel to print, matte laminate has a velvety sensation to its surface. The surface will be incredibly smooth to the touch and the way the light hits your product will be diffracted subtly and evenly.

While some people prefer the feel of a glossy laminate, there are a lot of people out there who love the texture of matte. Because of the popularity of gloss laminate, matte can be the more unique option.

Image credit: A to Z

Image credit: A to Z

It’s not just aesthetics. Laminate will increase the lifespan of your printed product by increasing its water-resistance and the ability to resist wear and tear. It will also reduce the effect of sun damage on your print colours.

Ultimately, this means a printed product which can maintain its luxurious image for longer and you have more time to impress your consumers before it starts looking shabby.

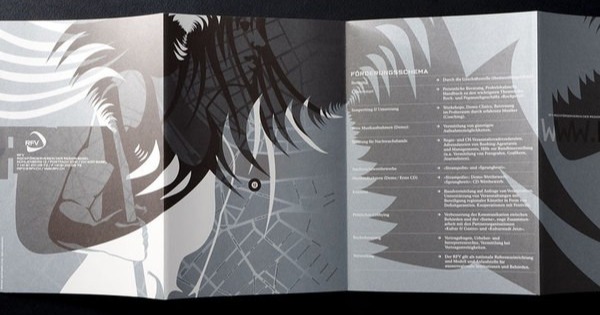

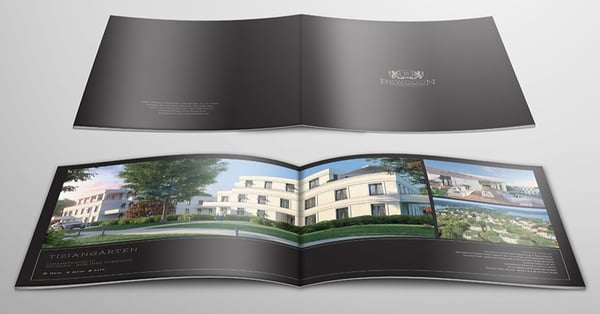

Saddle-Stitch

When deciding on a print finish for your method, it’s not only the visual impact you need to think about, but the practicality of your printed product as well.

Saddle-stitch is a way of creating leaflets, pamphlets or even books that are made by folding sheets together. The sheets are then stapled together with the staples passing through the folding crease and cinching together on the other side.

Image credit: Behance

Image credit: Behance

Using saddle-stitch for your leaflets or other copy is a simple and cost-effective way of creating something book-like. It’s possibly the least-expensive way of binding together print.

Anti-Scuff Laminate

The last thing you want is marks, scratches and fingerprints to spoil your print. This is where you can utilise an anti-scuff laminate as a finishing solution.

An anti-scuff laminate will extend the lifespan of print by protecting against any blemishes which makes it perfect for print that will be used often.

Image credit: Web Design Booth

Image credit: Web Design Booth

We recommend it as an alternative to matte laminate if your printed product features more solid and darker colours as it truly allows these areas to pop out of the page without drawing attention to any damaged areas.

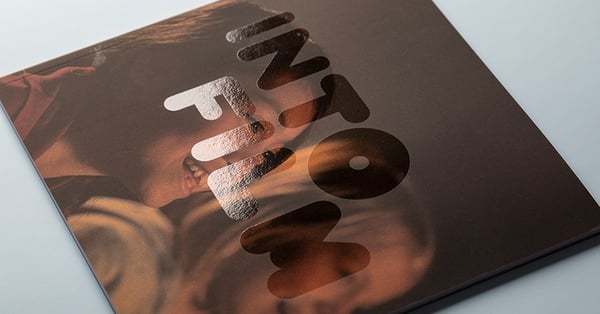

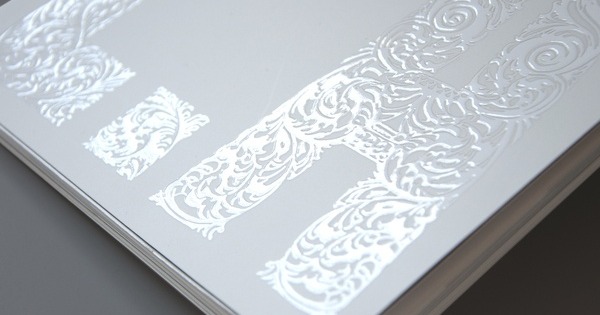

Soft-Touch Laminate

Soft-touch laminate is another luxury addition you can take advantage of for your printed products. This laminate instantly conveys quality by preserving colours, resisting marks and creating a lasting impression.

Image Credit: Pinterest

Image Credit: Pinterest

This type of finish is ideal for premium brands and helps to convey an up-market image. It’s a true all-rounder, working best with brochures, postcards, direct mail and anything using silk paper.

In the example we’ve included, you can see how a transparent soft-touch laminate can be overlaid on an image to create text without the use of a separate layer of colour. This allows you to keep an entire image intact, further creating an impressive and clever visual design.

Gloss Laminate

Adding a silky sheen to your print can create a spectacular finish to your printed product, allowing photographs and images to really pop from the page.

Using a gloss laminate will create a professional finish as well as preventing cracking and increasing water-resistance.

Image credit: Brunswick Press

Image credit: Brunswick Press

It’s the perfect finish for brochures and high-demand printed products as a gloss laminate creates a highly-desirable tactile surface which brings focus on artworks, digital images and photography. It’s the contrasting version to matte laminate and you can discover the differences between the two on our blog.

As a gloss laminate works to highlight colours very effectively, your print will be able to be truly striking. A real showstopper.

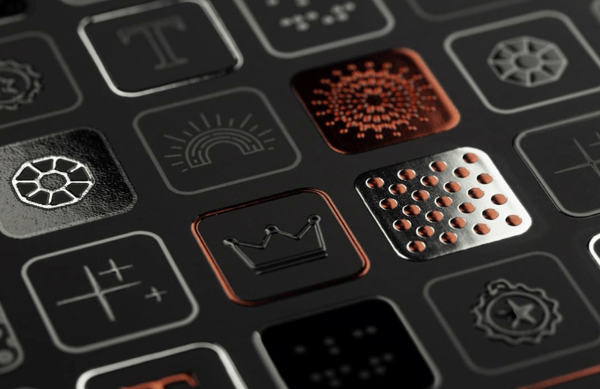

Spot UV Varnish

UV Varnish is similar to laminate in its look, but much different in the technical application. Like embossing, it’s a great way to draw the eye towards key elements such as logos or important text.

The process involves applying a varnish and then running the print under a UV light, which hardens the coating. Upon finalising, the varnish is able to catch any light and enhance the vividness of any colours used.

Image credit: WebFX

Image credit: WebFX

Using it against a matte background can help to create striking contrasts. You can even add glitter to the varnish for a unique surface layer.

This is what makes spot UV varnish ideal for any images or graphics you want to take centre stage in your printed product. It’s a brilliant print and finishing solution for decorative effects and works to reinforce perceptions of quality.

JET Varnish / Scodix

Jet varnish is another example of spot UV coating, but it can take your print into another dimension through being able to create impressive 3D raised effects, being printed from six to 100 microns in thickness.

Image credit: Scodix

The specially-designed varnish means that your images or designs can be physically ‘lifted up’ from the stock, also adding a higher sheen to the colours.

Using this finish creates an impressive and dynamic look to your print, going beyond the visual realm and into the tactile.

Binding Options

Finishing types is a moniker that doesn’t exclusively belong to how your print looks visually - it can also include the practical side of creating print. Here we’re talking about binding. If you’re creating brochures, magazines, leaflets, pamphlets or any other book-type item, you may need to look into what binding options are available to you.

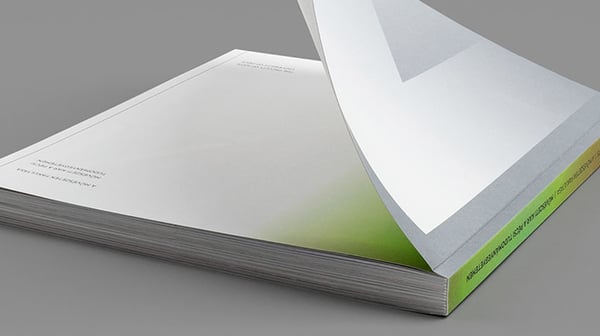

PUR bound

PUR binding is a type of binding that uses Polyurethane Reactive (PUR) adhesive. It’s a form of perfect binding where the covers and pages are glued together at the spine. They’re then ‘trimmed’ to achieve a perfect, uniform edge.

Image credit: Under Consideration

Image credit: Under Consideration

PUR is a brilliant binding method as it provides superior flexibility. This means that the spine doesn’t crack when your item is opened flat.

It’s also useful as it adheres successfully to a variety of paper types and finishes, such as ink, varnish, recycled paper or UV coated.

Spiral Bound

Spiral binding is a very common binding process which is also very cost effective. Commong things like notebooks and diaries are spiral bound. The process entails threading a wire through small holes punched through the stock.

Image credit: Bubu

Spiral binding is a very stable choice of binding. Choosing to use a thin wire in your design process can result in a very elegant item.

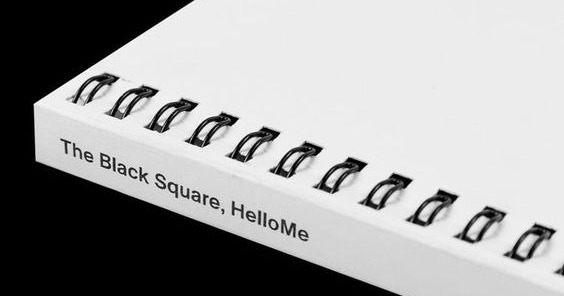

Wire-O Bound

Wire-O is similar to spiral binding in the use of wire threaded through the pages, but the design of the wire is significantly different in that two pieces go through one hole, rather than just one.

It’s a popular and practical choice, as it means the booklets can be opened around 360 degrees.

Image credit: DOMO-A

This arrangement makes it particularly useful when creating with different materials of varying weights and thicknesses. The colour of wire can be altered and even the shape of the perforations in the pages.

Singer Sewn Binding

Singer sewn binding is a traditional print and finishing solution used to bind your products and creates a highly stylistic and unique look to your printed products.

Image credit: Graphic Exchange

Just one or a number of threads are used to sew the pages together, resulting in a secure and stylish finish.

While offering a very secure and stable binding option, the thread can be incorporated into the print design, offering an opportunity to use complementary or contrasting colours. One of the main practical advantages of this binding choice is that the product can easily be opened flat every time.

A finishing solution for your printed products is one of the last parts of any effective printing method. The right printing technique can help you to achieve the best results.

If you're wanting to see some examples of the different finishes in action to help you decide, check out these case studies to see what other brands are doing.