There are so many printing techniques and, if you don’t know anything about printing, they can be difficult to understand. Offset printing is the most commonly used form of printing used today and, despite the digital age, printing is still a very popular and effective method of marketing.

When it comes to offset printing, a general rule is to produce runs of 1,000 or more pieces as the method is commonly used to print large quantities and is therefore more cost effective above this number.

As offset printing is the most commonly used printing process throughout the country; here’s a bit of information about how an offset printing machine works and the technique that it goes through to produce large amounts of high quality print.

What Does Offset Printing Mean?

With other printing methods the ink is transferred directly onto paper; however, with an offset printer, the process is a little bit different as ink isn’t doesn’t directly go from plates to paper but is transferred to a rubber cylinder before then printing onto the paper as it passes through the cylinder.

Therefore, instead of going from plate to paper in two steps, an offset printer transfers ink from plate to the middle cylinder before printing it onto the paper, reducing wear on the printing plate, prolonging its usable life.

So How Does The Process Work?

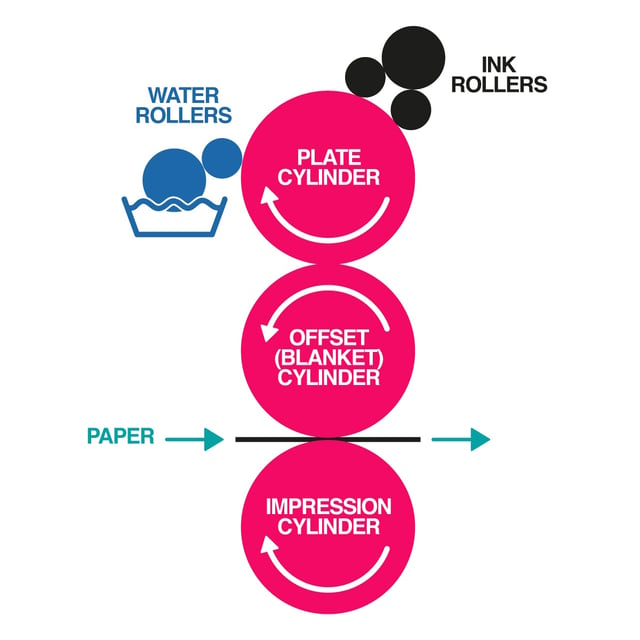

An offset printer includes three cylinders, a plate cylinder, an offset blanket cylinder and, finally, the impression cylinder. Like mentioned above, using these different cylinders is the reason why it’s called offset as there are three cylinders (rather than directly putting the ink onto the paper).

The process can be visualised in the graphic we have created below...

The plate cylinder is the first cylinder in the process. These cylinders have either a thin aluminium or plastic plate formed around the cylinder. From here, each plate is custom made containing the images and text that are to be transferred onto the paper. If you didn’t already know this then here’s a fun fact: ink and water do not mix; therefore, the plates have been treated so that certain areas attract ink and the other areas attract water which will then repel the ink.

The process consists of the plate cylinder spinning, making contact with rollers that distribute the water and the ink. Before the process begins the plate cylinder has to be specially treated. This means that when the plate cylinder makes contact with the water and ink rollers, the ink adheres to the images and the water then repels the ink from the areas where ink is not needed.

We now move onto the offset blanket cylinder. This second cylinder turns in the opposite direction to the plate cylinder that’s why it is named offset. This roller has a rubber blanket around it, therefore, when the two cylinders roll against each other, the water on the plate is squeezed away and the ink is then transferred onto the rubber blanket on the second cylinder. This then creates a mirrored image of the ink design which is now ready to be printed onto the paper.

We are now onto the final step of the printing process, which leads us to the third cylinder which is called the impression cylinder. Again this one then turns in the opposite direction to the blanket cylinder. The impression cylinder is made from clean steel which then presses paper against the rubber blanket transferring the ink. As this is the final process, the image has now been printed onto the paper.

Each ink colour applied to the paper has its own set of rollers placed above the plate cylinder.

How Does Offset Printing Help Schools And Colleges?

There are many reasons why offset printing is the most commonly used method of printing within the country, below are some of the reasons it can help schools and colleges specifically.

The More You Print The Less You Pay

Schools and colleges on average usually hold over 1,000 students and to get information across to these students and their parents is usually done through newsletters, flyers, booklets, and other means. Therefore, printing thousands of items manually on an office printer (or even on a professional digital printer) can be less efficient and more costly.

Offset printing is cheap and the more you print the less you pay since most of the cost is within the set up not the quantity of prints you need. As offset printing is mainly used for bulk printing; this method is great when you need to deliver a flyer to all the students within the school or college.

The Process Is Quick

Once the initial design has been transferred into the plate cylinder, getting it from there onto the paper takes a matter of seconds; therefore, a big batch can be completed and printed quickly. Perfect for those last minute print jobs!

It Produces High Quality Prints

Offset printing produces rich, high quality, images with accurate colours, sharp typefaces, and fine details. An ordinary printer would not be able to produce this level of quality. All of these aspects create quality looking pieces at affordable prices. When attracting students into your schools or colleges, having high quality brochures, flyers or booklets advertising the premises is more likely to impress potential students and parents, which then reflects well on the school or college.

Printing is necessary when it comes to schools and colleges as a form of marketing and getting information across to students and parents. Therefore, having a printing method that is cheap but delivers high quality is essential; this is where offset printing comes in. As it is a very reliable form of printing and can benefit schools and colleges due to delivering high quality results and because of the printing process can be done at a low price.

Offset printing is one of many different printing processes; discover other ways of printing by downloading our easy to read eBook that will introduce you to the world of printing.