To create the premium brochures and materials you and your business need to showcase your luxury products, choosing the perfect printing technique is vital. An ineffective print method can be the all-important difference between advertising luxury products in good quality, or in great quality. A solution is in place, and it’s a proven method for creating consistently perfect materials which will play a big role in selling your luxury products to their full potential. UV Curing is the answer - but what is it? And how is it used in printing?

.jpg?width=640&name=32%20W%20-%20SpringBoard%20(1).jpg)

Realistically, you can print your luxury brochures on any printer. However, be prepared to lose the luxury tag if you haven’t utilised the best possible printing technique to give your brochure the premium feel. And the stock you choose to use matters greatly.

To get the best possible results for your luxury brochure and advertise your products how they deserve to be shown off, then using the LED UV printing technique is what will make your brochures consistently perfect, and impress readers. So, it’s time to embrace the future of printing technology and make your products the finest in the market.

What Is UV Curing?

UV Curing is a technique that will continue to rise when discussing printing via an LED UV printer. It's the drying method the printing process uses and it plays a major role in perfecting luxury materials.

Ultraviolet curing is a photochemical process where the high-intensity UV light instantly cures - or dries - inks, coatings and adhesives. This method offers numerous advantages over traditional drying methods, as this method has been proven to increase production speed, reduce reject rates, facilitate superior bonding as well as improving scratch and solvent resistance.

The drying technique was originally introduced back in the 1960s, with more and more industries adopting the method ranging from automotive to electronics and telecommunications. It’s grown to become a multi-billion pound worldwide industry and continues to grow at a rapid rate, more than 10% per year, and has displaced the conventional water and solvent-based thermal drying techniques because of it’s increased productivity, improved product quality and performance, as well as the fact that it’s environmentally friendly.

How Does UV Curing Work?

LED UV uses an innovative drying method called UV curing which is proving very

successful. Instead of heat, ultraviolet light dries the ink and it only takes a split

second. The process improves the turnaround time and helps the ink retain its

depth of colour and quality. LED UV uses around 20% less ink than conventional

printing presses as the quick drying time reduces absorption and dispersion of

the ink into the stock.

The method dramatically improves physical properties, meaning your printed media will be shown off with an improved high definition finish.

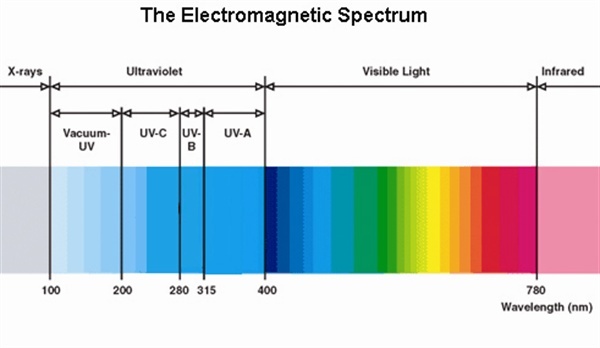

To go into slightly more depth, the UV light used comes from a particular portion of the light spectrum, usually considered to be in the wavelength range from 200nm (nanometers) to 400nm. In this range, the light has many important uses ranging from water purification, semiconductor lithography as well as adhesive curing - which is how it links with LED UV printing as the light instantly hardens the inks, coatings and adhesives.

Source: NailsMag

When it comes time for the UV lights to cure the adhesives, inks or coatings, it can be broken down into two parts. One section is the resin itself, and the second is the photoinitiator, which is already mixed in. The photoinitiator doesn’t react to the resin itself, it instead absorbs the UV light before anything can happen. Once the UV light is delivered, the photoinitiator undergoes a chemical reaction to cause the adhesive, ink or coating to harden.

Why Is It Used In LED UV Printing?

With more businesses like yours seeking that perfect print quality to showcase their brand or products, it doesn’t come as a big surprise that LED UV printing has emerged as a favourite, despite all of the technicalities behind it. The LED UV printers and the curing method play a vital part in enhancing the quality as only the highest-quality products are printed using this technique.

Ultraviolet curing is used in LED UV printing because the turnaround times are much faster, something companies prefer. LED UV technology is now so efficient due to its drying process that it can reduce the turnaround of the majority of high quality printing jobs by around 40 percent, while the quality isn’t compromised.

The curing technique ensures that once the printing process begins via the LED UV printer, the instant drying technique won’t sink the ink into the materials and helps enhance the colours, making them much sharper, brighter more vivid to provide the best visual presentation. This is a beneficial method for producing high quality materials to instantly grab the reader’s attention.

When you print via an LED UV printer, the curing method means 'ink set off' is a distant memory. This is when the ink transfers from one sheet to another, so this impressive technique makes sure the original characteristics remain on the materials as there’s no need to apply a sealing coat, and also eliminates the use of an anti-set off power spray. The spray creates dust, so ultraviolet curing helps that by making sure anything you produce doesn’t contain any unnecessary blemishes or marking that make brochures or leaflets look unappealing.

Curing plays a pivotal role in achieving perfection, as the cutting edge technology ensures it produces consistently stunning results to help achieve desired aims and make businesses stand out. The use of ultraviolet curing in LED UV printing is proving to be the future for marketing and showcasing premium products. Once printed, it’s easy to feel the superior quality and see the high quality imagery that’s only available with an UV LED printer.

Want to Know More About Printing? Take a Look at This

This guide tells you everything you need to know so that you can produce your own stunning printed content. Download it now.